Keywords: Cable Stayed Bridge, Suspension Bridge

1 Introduction

Cable-stayed bridge a

bridge in which the weight of the deck is supported by a number of cables

running directly to one or more towers.

Below

is table of few of the historical cable supported bridges, later on different

parts and types of bridge elements has been discussed in brief. Below we have

table showing major suspension and cable stayed bridge respectively till 2012.

2 Cables

The basic element for all cables to be

found in modern cable supported bridges is the steel wire characterized by a considerably

larger tensile strength than that of ordinary structural steel. Mostly 3-7mm

cylindrical wire is used, typically 5-5.5mm for main cable whereas up to 7mm

diameter used for parallel cable in cable stayed bridge. The wires are

manufactured by the Siemens–Martin process or as electro steel.

2.1 Types of cables:

a. Helical Bridge strands

Fabricated by successive spinning of

layers generally with opposite direction of helix, starting with a straight

core. Smaller pitch uses as compared with 7 wire strands. Strength is reduced

10% due to such configuration i.e. 0.9 fcbd where fcbd is

design stress of a parallel-wire strand of the same wire. Axial tension

increases length for the first time so to act ideally during service before use

these are subjected to overloading of 10-20%(pre-stretching).

b. Locked coil strands

There are two types of twisted wire at

core: round wire in helical pattern and at outer part: Z-shaped wire. Z-locking

makes it less sensitive to the pressure. These are always manufactured in full

length and full cross section.

Parallel wire strands

All wires are straight from end to end. It

had a lot of advantages but due to reeling problem this was used very late for

construction. These are formed in pattern of regular hexagonal, deformed

hexagonal, quasi hexagonal etc.

Parallel wire stay cables

These are more common in cable stayed

bridges than in suspension bridge. This has less integrity than the helical

strand so needs additional support like twisting the steel rope around the

bundle furthermore to give adequate corrosion protection the parallel wire has

to be surrounded by a tube and the void filled with a corrosion inhibitor

(Galvanized). The disadvantage of this is that diameter becomes more and weight

is also increased.

New PWS cables

1990’s variant of parallel wire stay wire

stay cable (slightly twisted) with a long lay to ease reeling and unreeling and

make self-compacting when subjected to axial tension. There seems to be

relationship between tensile force vs twist angle which is shown below in

graph. This is more compact than traditional PWS but has less equivalent

density.

Parallel strand stay cables

In principle composed in same way as

parallel wire stay cable with exception that individual 7 mm wires are replaced

by seven wire strands.

Bar stay Cables

Hardly used now and they contained 7-10

round steel bars each diameter 26.5mm,32mm or 36mm made of steel of yield

stress 1080MPa and tensile strength of 1230MPa with fabrication length 12m then

joined by threaded couplers. Bundled and placed in steel tube and grouted with

cement.

Multi-strand stay cable

These are used for large cable section

requirement and made of several helical strands in both cable stayed and

suspension bridges.

Parallel-wire suspension bridge main

cables

3 Cable System

3.1 Introduction

The selection of cable system is most decisive step in

design of cable supported bridges as this further dictates the amount of

material as well as type and maximum of loading that structure will efficiently

bear.

Quantity of steel:

Only three cable systems will be discussed: a)

Suspension system b) Fan system & c) Harp system.

For pure cable systems (with all elements as cables in

tension), subjected to uniform load, the theoretical cable steel quantity is

the same for the suspension system, and the harp system with equal horizontal

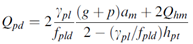

force. The formula given below is based on consideration of equal horizontal

force and also the inclination of cable has not been included. Furthermore, in

the formula the height(h) for the suspension system and fan system is same

while the harp system it is higher. This is just for understanding the

characteristics of the cable system but of no practical use as the pure cable

system is never used in cable stayed bridges.

Qcb = Theoretical quantity of cable steel, P = Vertical forces acting on

constantly spaced hangers, h

= Height of the system of cable chosen, λ = Distance successive hangers, γcb = Density of

the cable material, fcbd

= Design stress, n

= Number of cable elements

The harp system shows (in fig) the smallest quantity

and the suspension system the largest. The h/l values used in actual structures

are smaller than these values as the optimization must take into account the

material of the pylon. For the suspension system stiffness requirements furthermore

prescribe h/l values in the interval from 0.08 to 0.12.

If the

suspension system is changed to a fan system with the same height and with all

elements as cables in tension the cable steel quantity remains the same, as

stated in the previous theorem. But by replacing the horizontal cable elements

by the deck, the cable steel quantity is reduced to 69%. If finally, the pylon

height is increased to one-fifth of the span length, then the theoretical cable

steel quantity is reduced further to only 46%. Although the optimum height (hopt= λ) for the for minimum steel theoretically gives the value of inclination

to be 450 but while considering pylon contribution the more

realistic value for cable inclination which is also economical is 300 at

hopt= λ/√3. The case with hopt= λ has minimum deflection too which is 15% more in the case with hopt= λ/√3.

3.1.1 Stability of Cable system:

In traditional suspension bridge cable system may be

represented by the structural elements made of cables but parts of deck and

pylon should be added resisting axial forces induced by the horizontal or

vertical components of forces at the anchor points.

The cable system further can have 3 cases with above assumptions:

·

A cable system stable of the first order. In this

system, equilibrium can be achieved without assuming any displacement of the

nodes.

·

A cable system stable of the second order. In this

system, equilibrium can only be achieved with nodes displaced under the action

of the external load.

·

An unstable cable system. In this system, equilibrium

cannot be achieved by the cable system itself.

By analysing the different cases and system we can

conclude following:

·

The fan system is a system stable of the first order

but if the overall dimensions (ratio between side span and main span) are

chosen without respect to the relative intensity of the traffic load, an almost

complete release of the anchor cable tension might occur, and in that case the

idealized cable system will become unstable. Thus, this will need anchor cable

to restore its stability.

·

The traditional suspension system is stable of second

order, this will remain stable for loading cases.

·

The harp system is an unstable system but the fact that

harp system is unstable system does not imply that the total structural system

of the bridge is unstable, as the flexural stiffness of the deck and pylon will

add the stability.

·

In the total structural system of the bridge the cable

system only forms one part, and the total system can therefore very well show a

satisfactory load-carrying capability, even if the cable system is unstable.

However, it will be found that the global stiffness and the load-carrying

efficiency of the total system depend to a very large extent on the cable

system and especially if the deck is slender and has a modest flexural

stiffness.

3.2 Suspension system

In the traditional earth anchored suspension bridge

each main cable is supported at four points: at the two anchor blocks and on

the two pylon tops. The supporting points at the anchor blocks can generally be

assumed to be completely fixed both vertically and horizontally, whereas the

supporting points at the pylon tops often are represented best by

longitudinally movable bearings (due to the horizontal flexibility of the

slender pylon legs).

The main cable geometry can then be expressed by the

following equations,

where Ma(x), Mm(x), and Mb(x)

are the moments of simply supported beams with lengths la, lm,

lb subjected to the total dead load of main cable, hangers, and

deck.

where Mm(lm/2) is the simple

moment at the main span centre and hc - hD/2 the cable

sag at midspan.

3.2.1 Preliminary cable dimensions

In the process of designing a suspension bridge it is

advantageous to be able to make a quick, preliminary calculation of the cable

dimensions.

3.2.2 Quantity in the Pylon

When optimizing the superstructure of a suspension

bridge it is essential to take into account the variation in the quantities of

the pylons, whereas the quantities (per unit length) of the deck often remain

constant and consequently only influence the dead loads ga and gm

to be applied to the cable system.

Apart from above qualities of material may differ for

different conditions like height of pylon and cable material can be optimised

owing to sag ratio and unit rate of materials. Nevertheless, the size also

plays the significant role on the quantity of the materials required for the

chosen system of bridge.

3.3 Fan system

In cable stayed bridges the fan system has become the favourite

cable system due to its efficiency and the degree of freedom regarding

geometrical adaption.

3.3.1 Anchor cable

The anchor cable connecting the pylon top to the end

support plays a dominant role in the achievement of stability in the cable

system.

The dimensions of the system is influenced by the

stress ratio, above graph shows the variation of the critical side to main span

ratio (la/lm) with the traffic to dead load ratio (p/g)

and the stress ratio (Kac).

3.3.2 Preliminary cable dimensions

A preliminary design of stay cables can be based on

the same assumptions as those applied for the hangers of the suspension bridge.

3.3.3 Quantity in the pylon

The quantity of the pylon is

However, for the cable steel there is a difference due

to the higher cost of the corrosion protection and the large number of heavy

sockets in a cable stayed bridge.

3.4 Harp system

An unstable cable system, so that the flexural

stiffness of the deck and the pylons must be taken into account to achieve

equilibrium. The stability of bridges with harp-shaped cable systems can be

achieved in principle by two basic structural systems: either by applying a

stiff deck and a slender pylon, or by a slender deck and a stiff pylon.

3.4.1 Dead load geometry

To avoid unnecessary bending from dead load, the

geometry of the harp system is often chosen so that the dead load is balanced

completely. For a constant dead load this simply leads to a symmetrical

arrangement of the stays in relation to the pylon. For a difference between the

main span dead load gm and the side span dead load ga as indicated

in Figure below the balance is obtained if the horizontal component Hab

of stay cable AB is equal to the horizontal component Hbc of stay cable

BC:

Consequently, the distance between the cable anchor

points shall be inversely proportional to the square root of the dead load

intensity to obtain balance.

3.4.2 Interior support

The disadvantages of the harp system due to the

unstable cable system can be completely eliminated if intermediate supports are

added under all cable anchor points in the side spans, as indicated in Figure below.

The cable system will then change to a system that is stable of the first order.

3.4.3 Preliminary cable dimensions

In the preliminary design process the cross section of

the stay cables can be determined by equations similar to those found for the

fan system.

3.4.4 Quantity of cable steel

3.4.5 Quantity of the pylon

4 Deck

The deck is the structural element subjected to the

major part of the external load on a cable supported bridge. This is because

the total traffic load is applied directly to the deck, and in most cases both

the dead load and the wind area are larger for the deck than for the cable

system. Immediately the deck must be able to transfer the load locally whereas

it will receive strong decisive assistance from the cable system in the global

transmission of the (vertical) load to the supporting points at the main piers.

4.1 Flexural stiffness in the vertical direction

Action 1: to carry the load locally between cable

anchor points. Action 1 of the deck therefore corresponds to the action of

stringers in a truss bridge where the load on the bridge floor has to be

carried to the cross beams at the nodes of the main trusses.

Action 2: to assist the cable system in carrying the

load globally. Action 2 of the deck is found in bridges with unstable systems,

as has been described, e.g. for the harp system. Here the deck must be able to

carry a part of the traffic load not only between adjacent cable anchor points

but also between the main supports of the bridge.

Action 3: to distribute concentrated forces. The

deck’s ability to distribute concentrated forces (Action 3) will be utilized

primarily in bridges with a large number of cables supported points as found in

both the suspension bridges and cable stayed bridges at the multi-cable system.

4.2 Flexural stiffness in the transverse direction

The transmission of lateral forces from wind (or an

earthquake) acting on the deck and on the cable, system induces bending about a

vertical axis. Change from simply supported spans to continuous spans

significantly decreases the lateral deflection of the deck, the load carried by

the cable system will be reduced. Under lateral wind load the stay cables will

swing sideways to make the plane of the catenary coincide with the direction of

the resultant force from the cable dead load gcb and the wind load ucb,

as illustrated in Figure below. Consequently, the wind load will be transferred

to the cable anchor points in the same way as the dead load. Therefore, lateral

forces equal to half the total wind force 1/2ucbc will be induced at

the deck and the other half at the pylon.

4.3 Torsional stiffness

The torsional stiffness (and strength) required in the

deck depend to a large degree on the amount of torsional support offered by the

cable system. If the bridge has single cable plane then the torsional stiffness

of the deck is significant but if the bridge has two cable planes then the

torsional stiffness of deck is not important yet deck with torsional stiffness

is favourable for the overall stability.

4.4 Supporting Conditions

The interaction between the deck, the cable system and

the pylons in the transmission of vertical and horizontal loads is decisively

influenced by the choice of the supporting conditions for the deck. In the

conventional three-span suspension bridge the deck often consists of three

individual girders with simple supports at the pylons and the end piers (anchor

blocks). Generally, the end pier supports will be longitudinally fixed whereas

all other supports are made longitudinally movable, so that all expansion will

take place in the two joints at the pylons. In bridges with large longitudinal

forces a further restraint of the main span deck might be desirable. Such a

restraint could be accomplished in the following ways:

(1) By applying a fixed support at one of the pylons.

(2) By connecting the deck and the main cable through

a central clamp at midspan.

(3) By centering the main span deck by a device.

(4) By installing shock absorbers at the pylons,

allowing slow thermal movements but excluding movements from short-term loading

such as braking forces.

In self-anchored cable stayed bridges the maximum

axial forces in the deck occur at the pylons, and it is therefore not possible

to make the deck discontinuous at these points. Only at midspan in the region

between the two top cable anchors points will it be possible to arrange an

expansion joint, as the axial force is zero at that location.

5 Pylons

In principle, the pylon is a tower structure, but in

contrast to a free-standing tower, where the moment induced by the horizontal

loading (drag) from wind dominates the design, the most decisive load on a

regular pylon will be the axial force originating from the vertical components

of the forces in the cables attached to the pylon.

Relation between the relative pylon weight Qpl/Npt

and the pylon height hpl for different stress-to-density ratios is

shown below in the plot.

If the force transferred from the cable to the pylon

is acting in the plane of ABCD (the plane formed by centroidal axis of pylon

and deck) as shown above then the force on the pylon will still act along the B

but if there is presence of lateral load then the deck will deform and there

will be eccentricity to the force on the pylon and direction will shift toward

B’. Depending upon the system of the bridge structure the action of force on

the pylon and direction differs.

The pylons depending upon the fixity of base can have

different cases and similarly may have different action of force transfer

offering unique design conditions that allows certain pros and cons.

6 Cable anchorage and connection

The proper cable anchorage and connection between

pylon, deck and cables is very important and should be worked out carefully

with details. For in situ cables built up from individual wires at the site,

e.g. parallel-wire cables erected by the air-spinning method, the anchoring is

generally established by looping the wires around a strand shoe. For

prefabricated strands the most common way of anchoring is by socketing the ends

of the strands. The

fact that the high strength of the wire is achieved during the cold drawing

process implies that a strength reduction might appear if the metallic alloy

requires a high pouring temperature. Below (left) is the figure of the strand

shoe for anchoring stands erected by the air-spinning method. Another plot

shows the influence of poring temperature on the ultimate strength σu

of the wire.

0 Comments